Plant Ash Glazes

Growing Glazes

My work results from my PhD research at the University of Sunderland, where I explored ash glazes from arable crop waste, produced on the farm where I live near Richmond in North Yorkshire. Using the waste material left after harvesting field bean and pea crops, I have developed a whole range of glazes; some glossy and transparent, others dry with rich colouring. They are suitable for a wide range of stoneware clay bodies and are fired in the electric kiln to 1240C, Cone 7, a relatively low temperature for stoneware.

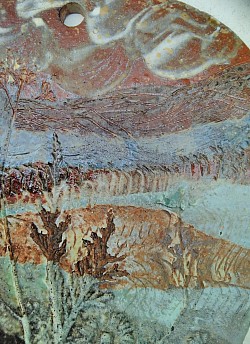

The textured surfaces of my pieces are also produced using waste products from the farm. Weeds or weed seed and chaff, dressed out of the harvested crops, are rolled into the soft clay. Further surface decoration makes use of other natural, locally found materials, such as clay slips and iron-bearing silts, poured or painted onto the piece.

Preparation of Ash for Glazes

The crops are harvested in autumn, when they are completely dried out, using a combine harvester which separates out the seeds and returns all the waste material onto the ground in rows. This 'straw', consisting of dried stems, leaves and empty pods, is collected and burnt in a bonfire to produce ash for the glazes.

Processing the Ash

In the course of my research I made the decision NOT to wash the ash, so as not to lose soluble potassium flux. Having collected the ash from the bonfire, it is passed first through a large kitchen sieve and then through a 40s mesh sieve. This process takes place outdoors and a dust mask is worn to avoid the harmful effects of the caustic ash.

The ash can then be stored ready to weigh out for glaze recipes.

Developing Ash Glaze Recipes

My definition of an ash glaze is one containing a significant proportion of ash, a minimum of 30% by weight, though the glazes that I now regularly use contain much higher percentages.

A useful starting point for glaze recipes is to create a line blend of 8 tiles, from 100% ash to 30% ash combined with Ball Clay, at 10% intervals. Other clays could also be used, for example a locally collected clay or a clay body.

Details of all Carol's ash glaze recipes and testing methods are included in her PhD thesis which is available in full online through the University of Sunderland on

Test bowls and discs of different stoneware clay bodies, all decorated with the same slips and glazes

Different Clay Bodies

Carol's PhD research was focussed on just three clay bodies, then in 2021, she decided to carry out an extensive investigation into the use of different clay bodies with her ash glazes, to explore how the underlying clay body effected the colour response and development of the glazes.

She gathered together over 20 different stoneware clay bodies, ranging from white stoneware to terracotta to black primitive clay, and from smooth to heavily grogged textures. Small dishes and discs of approximately 12-14cm diameter, were made from them, each decorated with the same four coloured slips, ochre and textures of Carol's landscape theme. The same four ash glazes were then poured over each of them, overlapping in some areas.

After glaze firing the tests to 1240C, Cone 7, Carol examined, photographed and analysed each one closely, noting the different colour responses and textures developed by each of the glazes on each clay. All the pieces gave acceptable results, with the most successful being selected to add to Carol's repertoire, expanding the range of her art practice.